Why DVT Matters for Small Businesses and Startups

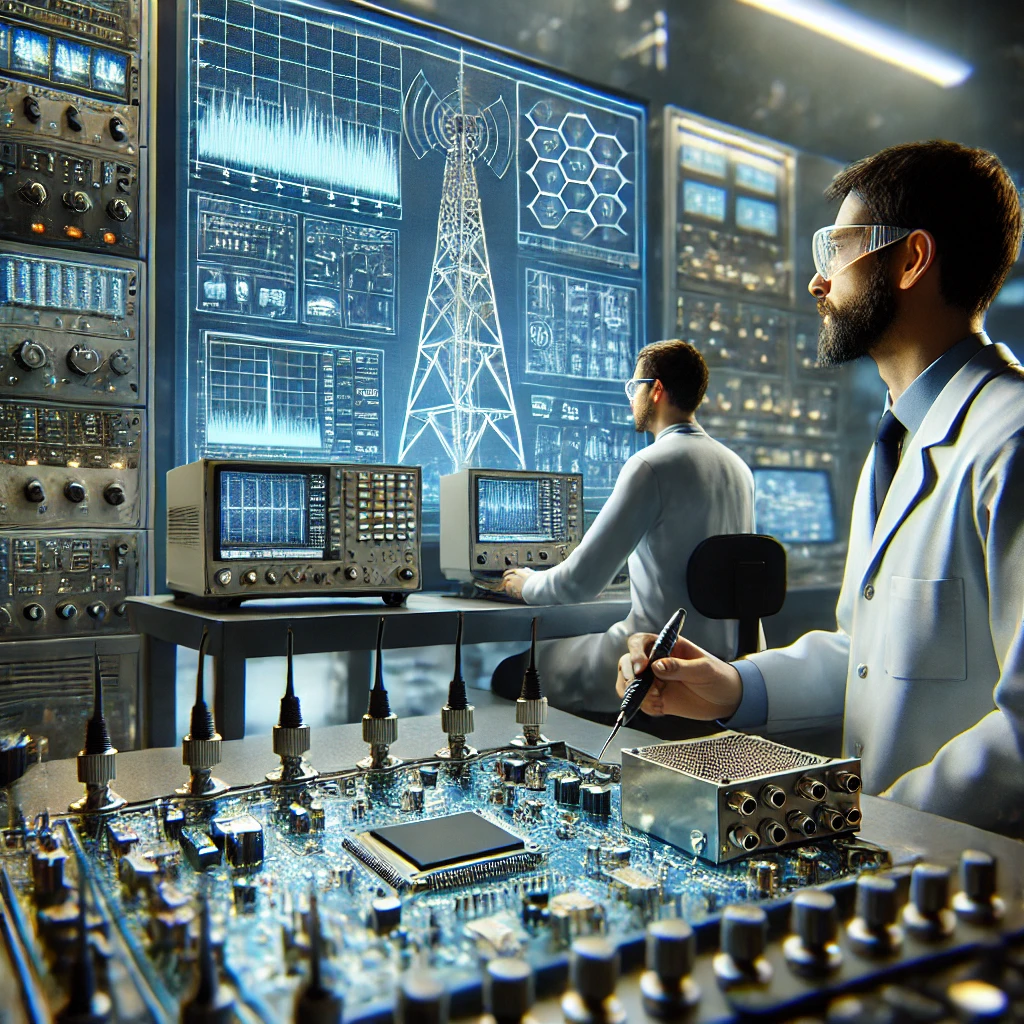

Imagine an RF transceiver designed to send and receive signals flawlessly. If there’s a flaw in the design—say, a misalignment in the frequency—it won’t function correctly, leading to communication breakdowns. Similarly, without proper DVT, your product might not perform as intended, leading to costly recalls or redesigns.

For small businesses and startups, resources are often limited. Investing time in DVT helps identify potential issues early, saving both time and money in the long run. It’s about ensuring your product is “tuned” correctly before it reaches your customers.

Essential Tips for Effective Design Verification Testing

1. Assemble a Diverse Testing Team

Just as an RF transceiver relies on both transmitting and receiving components to function, your testing team should encompass a range of expertise. Bringing in team members from different backgrounds can provide fresh perspectives, helping to identify issues that a homogeneous team might overlook.

2. Thoroughly Test All Requirements

Think of each requirement as a specific frequency your transceiver must handle. Missing even one can lead to malfunction. Ensure that every requirement outlined in your Requirements Document undergoes rigorous testing. This comprehensive approach guarantees that all aspects of your design are validated.

3. Develop Formal Written Test Procedures

A well-documented test procedure is like a schematic for your transceiver. It provides a clear roadmap, ensuring consistency and making it easier to replicate tests if needed. This documentation becomes invaluable, especially when scaling up production or when modifications are required.

4. Document and Address Design Changes

During testing, you might discover that certain “frequencies” aren’t being handled correctly, and need design tweaks. It’s crucial to document these changes meticulously. Update your design documents and retest to ensure that modifications align with the original requirements.

5. Conduct Design Review Meetings

After testing, gather your team for a design review meeting. This collaborative session allows for a comprehensive analysis of the results, fostering a deeper understanding and facilitating informed decision-making. It’s akin to calibrating your transceiver after initial tests to ensure optimal performance.

6. Utilize Available Resources

Leverage tools and templates designed to streamline the DVT process. For instance, Finish Line PDS offers a suite of resources tailored for small businesses and startups, including templates for test plans and requirements documents. These tools can significantly reduce the time and effort required to set up your DVT processes.

7. Seek Expert Assistance When Needed

If you encounter challenges during DVT, don’t hesitate to reach out for expert guidance. Engaging with professionals who have experience in product development can provide valuable insights, helping you navigate complex issues efficiently.

Common Pitfalls and How to Avoid Them

- Skipping the Requirements Document

Without a clear set of requirements, your DVT process lacks direction. It’s like trying to tune a transceiver without knowing the target frequencies. Ensure you have a comprehensive Requirements Document before initiating testing.

- Neglecting Extreme Environmental Testing

Products, much like transceivers, must perform under various conditions. Testing only under ideal scenarios can lead to failures in real-world applications. Incorporate environmental testing to ensure your product withstands different conditions.

- Overlooking Cost and Reliability Factors

While functionality is crucial, factors like cost and reliability are equally important. Ensure that your product not only works but is also cost-effective to produce and reliable over time.

- Ignoring Tolerance Stack-Up

Small deviations in components can accumulate, leading to significant performance issues. Pay attention to tolerance stack-up to ensure all parts fit and function together seamlessly.

- Using the Same Team for Design and Testing

Having the same team handle both design and testing can lead to oversight. Fresh eyes can spot issues that the original team might miss. Consider involving an independent team for the testing phase.

Leveraging Finish Line PDS Resources

To support your DVT efforts, Finish Line PDS offers a range of tools and services tailored for small businesses and startups:

- Design Verification Testing Services

Expertise to help you conduct thorough DVTs, ensuring your product meets all specified requirements. Learn more about their services here.

- Design Review Services

Offering fresh perspectives to identify potential issues early in the development process. More information is available here.

- Comprehensive Tool Library

Access templates and checklists designed to streamline your DVT process. Explore the available tools here.

By integrating these resources into your DVT process, you can enhance efficiency, reduce errors, and bring your product to market with confidence.

Conclusion

Design Verification Testing is a critical step in the product development journey, especially for small businesses and startups. By approaching DVT with a structured plan, leveraging diverse expertise, and utilizing available resources, you can ensure your product is ready for the market. Remember, a well-executed DVT process is like a finely tuned RF transceiver—ensuring clear, reliable performance in the real world.

For more information and assistance with your DVT process, contact us today!

This is very useful