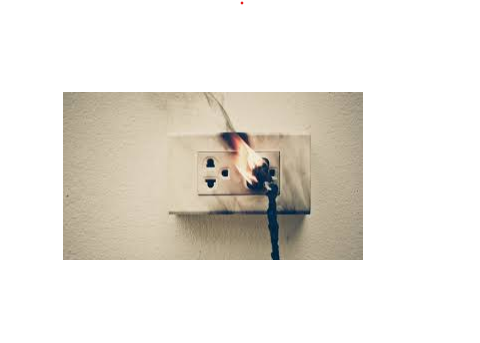

What went wrong

It’s essential to understand all the circumstances of the failure. Collect as much information as is practical. Details are crucial to be able to reproduce the failure in the lab. Avoid jumping to early conclusions before all the data has been collected.

Why did it go wrong

In engineering speak, this is called “Root Cause Analysis.” It is essential to understand that you need to discover the most fundamental issue — the first mover as it is often called. For example, saying that Q1 failed is not enough — we must know why Q1 failed. A better answer would be Q1 failed due to overcurrent because of tolerance stack up issues that resulted from an inadequate design checklist.

What will we do to make sure it does not happen again

The QA guys call this “Corrective Action.” What actions are you going to take to make sure this type of failure does not occur in the future? For example, a Corrective Action might be to add a procedure to the design process that includes Moto Carlo analysis to understand the tolerance stack up and its effect on component stresses.

Follow up with the customer

No customer has a right to expect perfection — we are only human. However, they can expect that you continuously improve. In today’s world of public knowledge, reviews, and the Internet, you cannot afford to have any bad press. Follow up with the customer and explain what you have done to make sure the problem they experienced will not happen again.

0 Comments